In the ever-evolving landscape of manufacturing and technology, UV curing systems have emerged as a game-changer, revolutionizing various industries by providing a swift, efficient, and environmentally friendly solution for curing adhesives, coatings, and inks. This blog delves into the fascinating world of UV curing systems, exploring their applications, benefits, and the transformative impact they’ve had on diverse sectors.

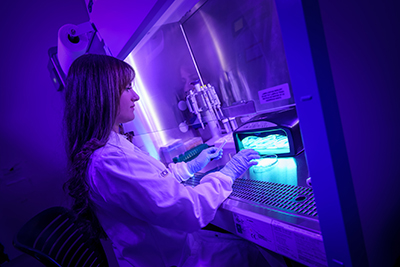

Understanding UV Curing Systems: UV curing is a photochemical process where ultraviolet (UV) light is used to instantly cure or dry inks, adhesives, and coatings. This process involves the use of specially formulated materials that respond to UV light, creating a rapid and durable bond or finish. UV curing systems typically consist of a UV light source, a conveyor system, and the substrate to be cured.

Applications Across Industries:

- Printing and Packaging: UV curing systems have become indispensable in the printing industry, offering high-speed curing for inks and coatings on various substrates. This results in vibrant and durable prints on materials such as paper, cardboard, and plastic, while also enhancing production efficiency.

- Electronics Manufacturing: The precision and speed of UV curing make it ideal for electronics manufacturing. UV-curable adhesives and coatings ensure quick and reliable bonding in the assembly of electronic components, contributing to the production of compact and high-performance devices.

- Automotive: In the automotive sector, UV curing systems are used for clear coat applications, ensuring a fast and flawless finish on vehicle surfaces. The rapid curing process reduces production time, enhancing overall efficiency in the manufacturing process.

- Medical Devices: UV curing plays a crucial role in the medical device industry, where precision and reliability are paramount. UV-curable materials are used for bonding and coating medical equipment, ensuring the integrity and longevity of these critical devices.

Benefits of UV Curing Systems:

- Speed and Efficiency: Perhaps the most significant advantage of UV curing systems is their unparalleled speed. Traditional curing methods often involve lengthy drying or curing times, whereas UV curing achieves instant results, significantly reducing production times and increasing throughput.

- Energy Efficiency: UV curing systems are energy-efficient compared to other curing methods. The focused and targeted nature of UV light minimizes heat generation, resulting in lower energy consumption and reduced environmental impact.

- Enhanced Quality and Durability: The rapid curing process of UV systems contributes to the creation of high-quality finishes. The cured materials exhibit superior adhesion, scratch resistance, and overall durability, making them ideal for demanding applications.

- Environmentally Friendly: UV curing is a solvent-free process, reducing the emission of volatile organic compounds (VOCs). This environmentally friendly aspect aligns with the growing emphasis on sustainable and eco-friendly manufacturing practices.