In today’s fast-paced manufacturing landscape, efficiency is paramount. Industries ranging from printing and electronics to automotive and medical rely on rapid and reliable curing processes to meet demands and maintain quality standards. Enter UV curing systems: the game-changer in the realm of industrial curing solutions.

Unveiling the Technology

UV curing systems utilize ultraviolet (UV) light to initiate a chemical reaction that instantly cures adhesives, coatings, and inks. Unlike traditional curing methods that rely on heat or solvent evaporation, UV curing offers unparalleled speed and precision. The process is swift, with curing times measured in seconds rather than minutes or hours, leading to increased productivity and reduced production times.

Versatility in Applications

One of the most significant advantages of UV curing systems is their versatility. From curing inks on packaging materials and printed circuit boards to sealing and bonding components in electronics and automotive assemblies, UV curing finds applications across a myriad of industries.

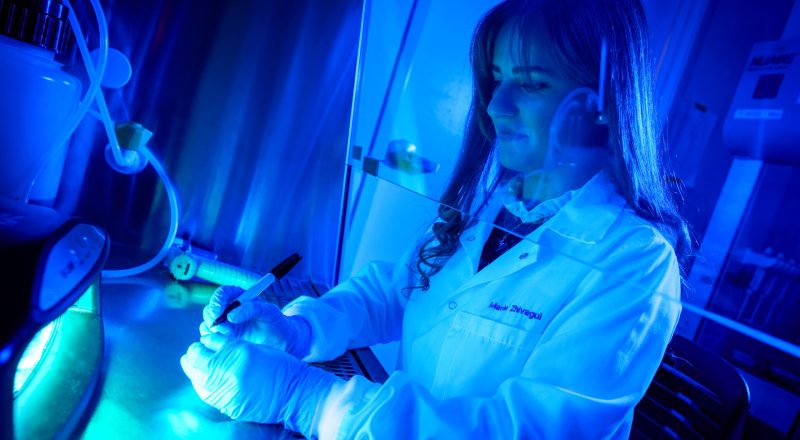

In the medical field, UV curing systems play a crucial role in manufacturing medical devices, dental materials, and diagnostic equipment. Their ability to provide rapid, uniform, and sterile curing makes them indispensable in the production of life-saving medical products.

Precision and Performance

Precision is paramount in industrial manufacturing, and UV curing systems deliver just that. By harnessing UV light, these systems offer precise control over the curing process, ensuring consistent and uniform results with every application. This level of accuracy not only enhances product quality but also reduces material waste and rework, ultimately driving down production costs.

Moreover, UV curing systems are known for their reliability and durability. With minimal maintenance requirements and robust construction, they provide long-lasting performance, making them a cost-effective investment for businesses of all sizes.

Sustainability and Safety

In an era where sustainability is a top priority, UV curing systems shine bright. Unlike solvent-based curing methods that release volatile organic compounds (VOCs) into the atmosphere, UV curing is solvent-free and environmentally friendly. It eliminates the need for harmful chemicals, reducing air pollution and minimizing carbon footprint.

Furthermore, UV curing systems are inherently safer for operators and the workplace. With no heat involved in the curing process, there is minimal risk of fire or thermal damage to sensitive materials. Additionally, UV curable adhesives and coatings are non-toxic and emit no harmful fumes, creating a safer working environment for employees.